While there are many injection molding companies, GripWorks offers more options for your custom plastic parts. As a multi-process manufacturer, analyzing the specifications for a project includes many factors to determine which process is the best fit. These factors include costs, time, volume, materials, time to market, and so much more.

Benefits of Injection Molding

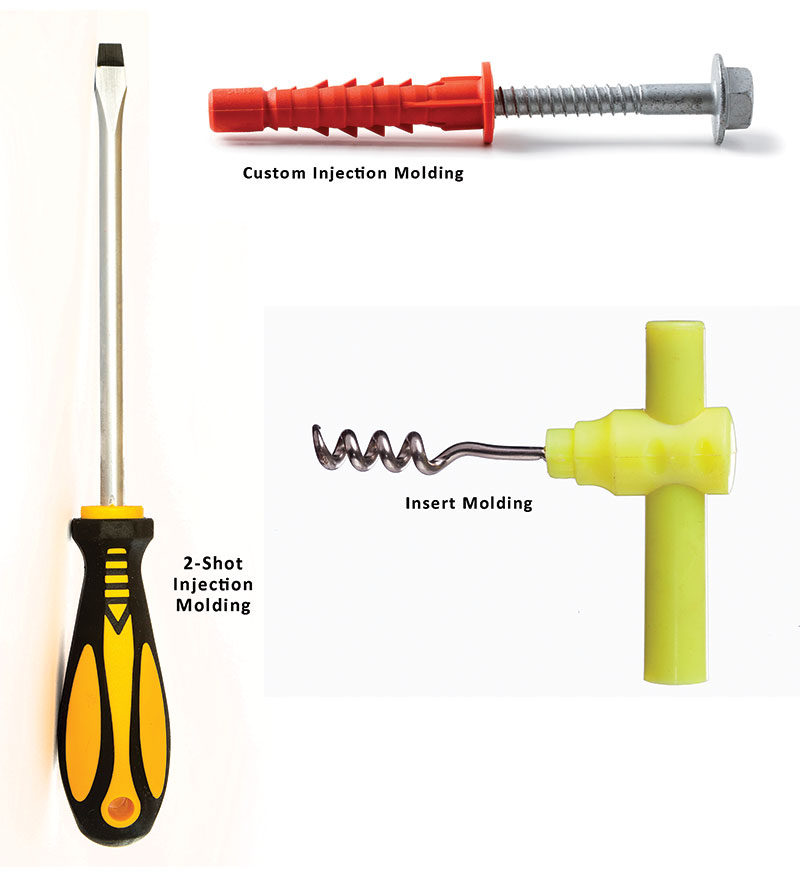

When an analysis of a project suggests injection molding is the right choice, the next step is to determine what type of injection molding produces the best result.

Types of Injection Molding Provided by GripWorks

Terms are often used interchangeably and the term “overmolding” can be considered both 2-shot and insert molding.

Injection Molding is almost always Custom Injection Molding

Although the GripWorks line of injection hand grips is stocked and available to purchase online, most injection molded parts perform a specific function making custom the default choice. Factors considered for injection molding include:

- Volume – tailored for producing large volumes of parts

- Tooling – capital investment upfront, offset by substantially lower piece price

- Material – low material waste

- Tolerances – tight tolerance requirements are met at the highest level

- Machine type

Types of Injection Molding Machines and Why the Choice Matters

Injection molding machines are uniquely designed for specific performance. In a somewhat analogous explanation let’s use dogs and cats as relates to materials. Dogs and cats are fed different foods just as various machines are fed different materials. Again, using the same analogy, the size of a dog determines the size of the food/water bowls. Likewise, machines are designed to handle various size molds to produce specific size parts. Watch for more about machines in the coming months.

Still want to know more? Follow the links above for additional details.

Please call or visit to learn more about each type and the features that help GripWorks produce parts that best meet the requirements.

Our production capabilities for injection molding in our USA and Southeast Asia facilities are wholly owned and operated.