With the Thermoplastic Injection Molding concept in mind, we explore the addition of placing an object into the process. A component or insert is placed into the mold prior to the resin entering the cavity. Once the material is injected it surrounds the insert and the part is formed. This image depicts two different examples of insert molding. In one of the knobs, the small threaded bronze colored hardware is placed or inserted into the mold, then the liquid is injected. This black knob with the threaded hardware securely embedded has become a single part.

The second knob or handle has a threaded post inserted into the mold prior to the liquid injection. It isn’t uncommon to find this type of handle in many household assembly projects, such as adjustable tables, stands, or other furniture.

Why Choose Insert Molding?

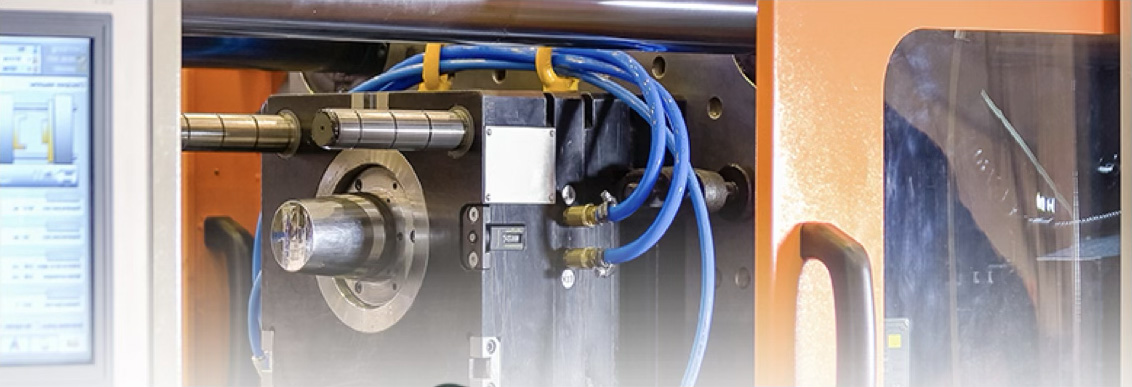

Industrial reasons for insert molding are many and in this next example the rod is inserted into the mold and the clear plastic forms around it to become a single part.

Some everyday basic examples of this include kitchen utensils, pots and pans, and many other household and industrial items, too.

Insert injection molding or simply insert molding is best automated with robotics. However, if volume is small, it is possible to manually place the part in the mold. While injection molding best serves large production runs, the need for an insert with tight tolerance may supersede the volume requirement. GripWorks will provides the guidance to alleviate your concerns when designing and producing your insert molded parts.

It is worth mentioning that insert molding is interchangeably used with the term overmolding or overmold injection molding.

Our production capabilities for injection molding in our USA and Southeast Asia facilities are wholly owned and operated.