What is 2-Shot Injection Molding and How Does It Work?

Understanding 2-shot injection molding is helpful to first know why someone would want to use this process to produce a product. Aside from the upscale visual appearance and branding for promotional reasons, sometimes necessity compels this choice. At times, a single part needs to perform while simultaneously functioning in different ways. Consider how a power tool protects the power source with a strong, sturdy casing, but from the user’s perspective, a soft, comfortable grip is desirable. Regardless the reason, the effect is like having two parts in one.

Equipment

The most common injection molding machines are capable of molding one material. GripWorks 2-shot injection molding machines will process two materials for one job. Some machines can manage 3 and even more. All GripWorks machines can process one material, and all our machines can produce insert molding. The flexibility of the 2-shot injection machines allows for both single injection and dual injections. This gives GripWorks the opportunity to supply in volume as needed.

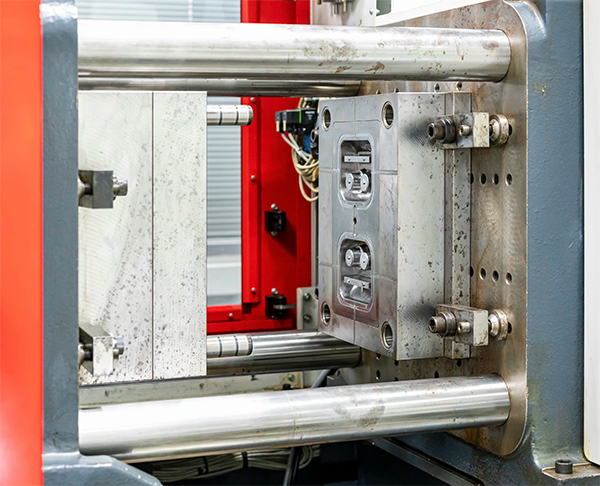

Injection molding equipment at GripWorks includes both horizontal and vertical clamp machines. The machine type is defined by the direction of the clamp upon opening and closing. In this image of a horizontal machine, the molds close on a horizontal line, side-to side vs. up and down. Vertical clamp machines, on the other hand, open and close from top and bottom, facilitating the insert or overmolding features. Although the horizontal clamp machines could produce an insert molded part, it would require a mechanism to hold the item in place.

Molds are uniquely designed for each part, as guided by the customer’s requirements. The size of a part to be produced will factor in the mold design, and this in turn factors in the equipment capable of handling the stated size. Each machine is equipped with platens which are firmly attached to the machine. Molds are independent from machines and only secured to the platen when the job is scheduled for production. The mold-bearing platens are directed to open and close during production and this can be automated or manually controlled. When the job is complete, the mold halves are removed from the platens to change out for other jobs.

Injection molding equipment is also subject to the type of materials that can be processed. In a previously mentioned analogy, dogs eat dog food, and cats eat cat food. Likewise, machines are different and designed for specific materials. This is yet another factor our design team considers. Precision, material type, and machine compatibility all converge to select the right machine, which is as critical as the design of the mold.

Case in Point

In this example, the blue portion represents the part that needs to be firm and is referred to as the substrate. The grey portion is where the hand wraps around the unit to turn to secure to a faucet or nozzle. Sturdy on the inside, but a rubbery flexible outside.

The setup for this part involves securing the mold to the machine platen, and since this is a 2-shot injection molded part, there are multiple platens. This particular machine is constructed with four stations and two sections containing mold-bearing platens are across from each other. One of the other two sections is set up to accept the finished part, while the fourth section may be used but is not necessary (for this part).

Of course, two materials are involved, each supplying one of the molds held by each platen. In the process to produce this single part, the first mold is injected with the blue color material. The mold is constantly cooled with water as the supplied coolant delivered by multiple hose systems. Seconds pass while the injection occurs, then more seconds pass as the cooling environment into which it entered causes the hot liquid to solidify. It is truly remarkable that the material can convert from solid to liquid to solid, in seconds. Either manually or at preset timing, automation triggers the rotation of the molds to the next station.

As the first station repeats the process, the second station continues cooling, and the substrate hardens. The turret rotates again to the third station. Here the second material/color is injected into the mold, which contains the substrate, and after the set time the platen opens, and the rotation of the mold advances the finished part to the final station where it is ejected for boxing.

The key is the rotation of the molds. The rotation of the turret (sometimes called the carriage, shuttle or carousel) allows for the second injection. The result is a single part composed of two different resources. It’s shots of two different injection steps joined to become a single distinct part. In this particular design, the convergence into a single unit is strengthened by the flow of the grey colored material into the horseshoe-shaped portion of the substrate. The material do not just meet, they merge further enforcing the bond as one unit.

The option to produce a part that is both sturdy and soft is of great benefit, but another reality is how much aesthetics improves the attractiveness of the product. If you think back over time, a simple screwdriver included a strong, sturdy handle. Advance to the current day and many handles of screwdrivers are composed of a softer rubber-like material. Purpose and appearance. The older tools are hard and dull, but today’s handles add comfort and vibrance with colors. These features draw attention to retail shelves, improving sales, something retailers and manufacturers seek.

Function is another primary feature of the 2-shot injection molding process. In the previous example of the blue/grey hose guard the function for securing the hose to the faucet (blue) increases while the function to prevent the hose from bending or kinking (grey) greatly improves because the interior of the grey portion is firm while the exterior is composed of comfort gripping material making it easy to grasp and turn.

Our production capabilities for injection molding in our USA and Southeast Asia facilities are wholly owned and operated.